Purpose of the program

Zero4 is a five-year ecosystem program led by Konecranes. Our objective is to increase industrial productivity through the sustainable improvement of material flows. Zero4 strives to advance digitized material flows that connect automation islands, eco-efficiency, and employees to productivity development.

Program background

Industrial productivity growth has slowed down in developed countries, having major implications for the global economy. However, the world not only faces the challenge of stagnating industrial productivity but also increasing energy needs, growing resource consumption, and rising emissions.

While past productivity gains came from more efficient equipment, automation, and enterprise resource planning systems, this growth potential has already been utilized.

Material flows driving innovation

Businesses now play a crucial role in driving the next wave of innovation to address both stagnating productivity and growing environmental pressures.

One of the most impactful areas where innovation is needed is in material flows. This is because all production processes depend on moving raw materials and products. These flows represent nearly 10% of company turnover, generate about 5.5% of global greenhouse gas emissions, and cause 40% of injuries in manufacturing. Improving the efficiency, safety, and sustainability of material flows therefore presents a major opportunity to boost industrial productivity while significantly reducing emissions

Industry challenges we are tackling

Societal impacts

Zero4 is redefining the role of humans in the future factory. As part of the program, lighthouse and model factories are being set up, with Konecranes' Business Factory as the blueprint. The aim is to increase industrial productivity while also creating hundreds of new jobs over the next five years in Finland.

Environmental impacts

The program targets reducing greenhouse gas emissions both within Konecranes’ operations and throughout its value chains. Zero4 also supports increasing the carbon handprint of Konecranes, the ecosystem, and the companies deploying the solutions. In addition, it focuses on increasing energy efficiency and reducing the use of harmful substances.

Economical impacts

The program contributes to increasing Finnish R&D investments by hundreds of millions of euros and to commercializing new solutions and technology. It plays a role in enhancing the international competitiveness of Finnish companies and in significantly increasing the export of material flow solutions

Program themes

Information Barriers

Information barriers refer to the currently widespread miscommunication or lack of any connection between humans, equipment and various control systems that exist in and between plants and ports. As these actors are not connected, it is not possible to optimize material flows to a meaningful degree. There is currently no single system connecting all material flow equipment and humans.

Removing information barriers means creating a material flow platform that can detect and instruct every single actor in the material flow. Removing information barriers enables the optimization of material flows, which is the single most promising way to increase industrial productivity.

GHG emissions

Obtaining and transporting raw materials and works-in-progress between the stages of production are a major source of GHG emissions and resource consumption. The manufacturing industry contributes more than 35% of global CO2 emissions and consumes nearly one third of energy on a global scale. Material flows are responsible for 5.5% of GHG emissions in the world.

Material flow equipment and maintenance activities still use fossil fuels and carbon-intensive materials, especially in ports. To make material flows more sustainable, all future material flow solutions and equipment must heavily favor renewable energy sources and sustainable materials.

Wasted energy

Zero wasted energy aims to reduce the amount of energy needed by material flows to the point that energy is only used to overcome the kinetic friction of the equipment. Material flow equipment wastes energy on unnecessary, unoptimized movements. Any waste of energy is a waste of valuable resources, regardless of the source. Optimizing material flows to be as efficient as possible will simultaneously reduce wasted energy.

Safety incidents

The reduction of safety incidents is of vital importance as material flows are currently responsible for 40% of injuries in the manufacturing industry. 74% of incidents that involve humans happen during routine job activities. Dangerous environments not only pose a risk to humans working in them, but also deter future workforce from seeking out careers in industries involving material flows.

Incidents involving company assets such as products and machinery cause business disruptions. These are all factors that have an immense impact on industrial productivity as they lead to injuries, delays and asset damage.

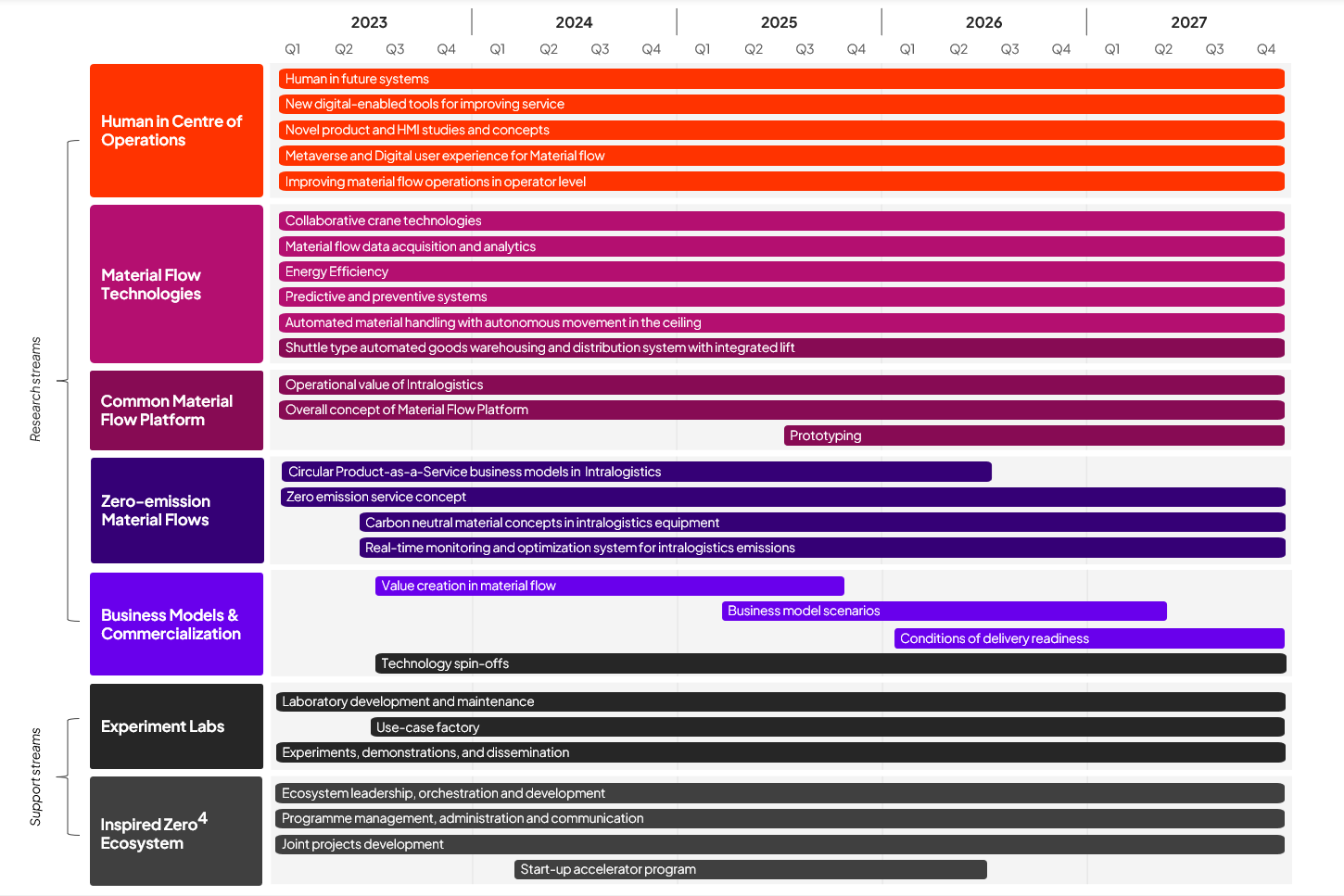

Program roadmap

The roadmap below provides an overview of the research topics and share of cooperation between Konecranes and ecosystem partners. The program's research and innovation activities are happening in seven research streams. Each stream contributes to one or more of the key deficiencies identified in the program: information barriers, GHG emissions, wasted energy, and safety incidents.

Research streams

Explore the seven research streams below to see how we are transforming industry challenges into concrete research and development efforts.

Human in Centre of Operations

This stream focuses on placing people at the core of future material handling. As automation, AI, and the industrial metaverse bring the physical and digital worlds closer together, the role of humans – and the ways we interact with machines and systems – is changing. The stream's aim is to create intuitive and empowering user experiences that keep humans in control while enabling the full benefits of next‑generation technologies.

Current research activities include the HiFive and the AiWo programs, both centered around investigating human-AI collaboration and its implications for the future of the industry.

Material Flow Technologies

This stream focuses on developing the core technologies that increase automation levels and improve safety in material handling. By enhancing how information moves between devices and enabling more intelligent interaction through sensors and data, the stream aims to raise productivity and energy efficiency across operations. The work also supports optimizing maintenance and reducing resource use through better data acquisition and utilization.

Current research activities include MixedFleet, a project focused on studying how autonomous machines and human workers are working together in the same workflow. Additionally, the stream produces environmental data that is further utilized by the Common Material Flow Platform stream.

Common Material Flow Platform

This stream focuses on defining a software solution that connects critical factory systems and delivers essential information about production status and material movements inside factories. Its purpose is to address inefficiencies by revealing bottlenecks, delays, and other disruptions, with the goal of achieving full visibility across factory operations. The novelty comes from combining data from IT and OT systems – traditionally optimized separately – and enriching it with tracking and tracing information from material flows.

Research in this stream is twofold. One side focuses on creating near real-time information from material, equipment and people movements by researching different tracking and tracing technologies such as cameras, lidars and tag-based solutions. Other part of the research focuses on the integration platform, standard architecture models, data sharing standards and legal framework.

Zero-emission Material Flows

This stream focuses on creating concepts for zero‑emission material flows by exploring circular business models, new service concepts, carbon‑neutral materials, and monitoring and optimizing the intralogistics emissions. By reducing emissions across the machinery value chain, the work also supports partners in moving toward zero emissions.

The research in this stream covers four areas: circularity‑based business models and the tools needed to support them; reliable methods for calculating emission‑reduction impacts; investigating alternative, carbon‑neutral materials for components and structures; and developing data capabilities for real‑time emissions monitoring and environmental information management.

Current research activities also include the DaRe‑X co‑innovation project, which focuses on data‑driven Re-X processes and circularity metrics using digital‑twin lifecycle data.

Business Models & Commercialization

This stream focuses on identifying customer‑centric business models that enable the commercialization of ideas emerging from the research‑driven and co‑innovation‑focused streams. Its purpose is to ensure that the outcomes of the program can be transformed into viable, valuable offerings for customers.

Current research activities include developing methods for measuring and improving RDI performance.

Experiment Labs (Business Factory)

This stream focuses on creating hands‑on cooperation that enables concrete knowledge, experience, and idea sharing in lab environments. It gives co‑developers and customers the opportunity to see and try new technologies in practice, ensuring that the solutions being developed deliver real value.

The Business Factory, which is part of this stream, is Konecranes’ new flagship site dedicated to boosting innovation. It provides a space where the latest technology research projects can be demonstrated, tested, and co‑developed together with partners.

Current research activities involve offering facilities for testing and exploring material‑handling and intralogistics solutions, supporting research across these themes as part of the broader program.

Inspired Zero4 ecosystem

This stream serves as an administrative and coordinating function that supports all other research streams. Its role includes preparing co‑innovation, co‑research, and EU‑funded project initiatives, managing the partner ecosystem, and handling both internal and external communication. The stream ensures that the Zero4 program stays aligned with its defined objectives and company strategy and is responsible for all related reporting.

No research activities are currently ongoing in this stream, although research would be possible if needed.